Piping Design & Stress Analysis

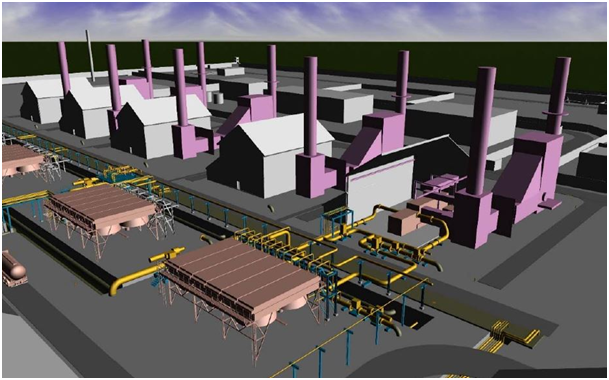

Piping routing and stress analysis studies starts after P&ID Rev 1 issue and material selection study completion. PPD uses 3D plant modelling software for routing and stress analysis software to ensure piping system works under process conditions, start-up / shut –down cycles and dynamic loads such as earthquake.

Maintanence and safety margins on site are taken into account during pipe routing and equipment placement studies.

Stress analysis studies conduct considering line list. Accordingly with fluids temperature and pressure values analysis conducts in detail.

Level 1 : Visual Analysis

No stress analysis is required. The piping lines are routed and supported by piping designers as per usual practice.

Level 2: Simplified Analysis

This method includes the use of charts, cantilever method or simplified formulae.

Level 3: Detailed analysis

Detailed analysis by computer program shall be carried out.