Jet Fuel Piping Stress Analysis And Modification

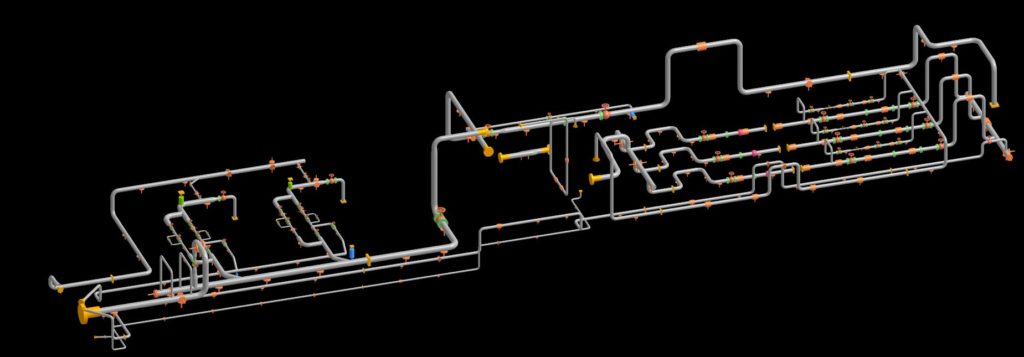

Design and stress analysis of Jet Fuel piping. Determination of types and locations of supports, pump nozzle stress check tasks are completed.

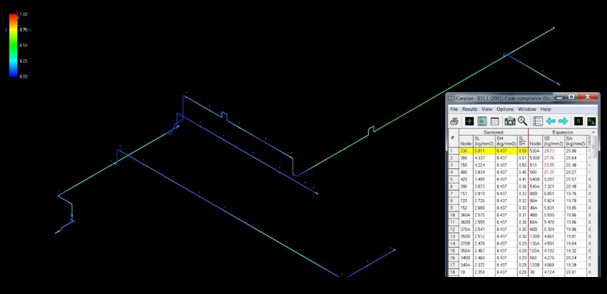

Wellhead Production&Separation Piping Design and Stress Analysis (ASME B31.1)

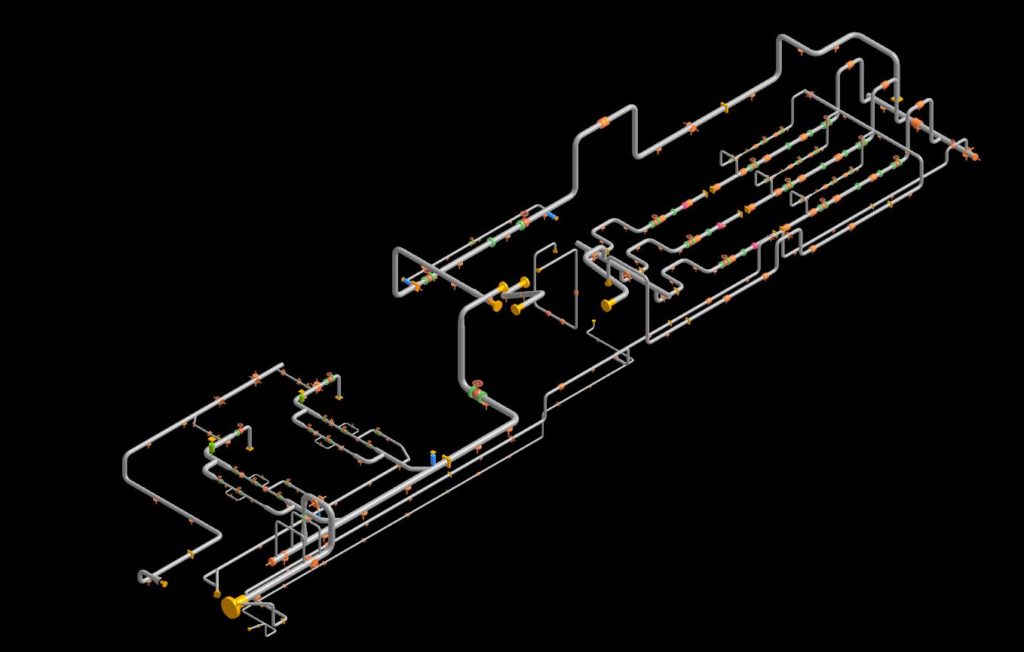

Design and stress analysis geothermal power plant’s re-injection pumps piping system.Pressure 39 bar Temperature 190 C.

Static Stress Analysis : Determination of types and locations of supports, pump nozzle stress check tasks are completed. Nozzle stress checks of accumulation tanks and separator tower. Pipe rack stress analysis tasks and determination of steel beam sections are completed.

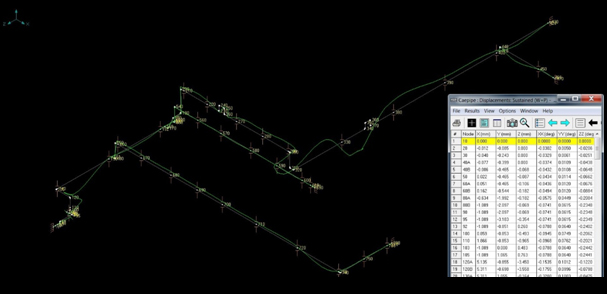

Brine, Steam and Condensate Line Stress Analysis And Modification (ASME B31.1)

Design and stress analysis geothermal power plant piping system.

Static Stress Analysis : Determination of types and locations of supports, pump nozzles, accumulation tank nozzles, seperator column nozzle stress check tasks are completed. Pressure 82 bar Temperature 120 C

Dynamic Analysis : Modal analysis of vibrations on brine wells. Selection of spring hangers accordingly with vibration analysis results.

Hot Oil Piping Design & Stress Analysis (ASME B31.1)

Hot oil piping design temperature increased up to 320 C from 280 C . Necessary modifications required are listed out. Additional required equipments are listed out.

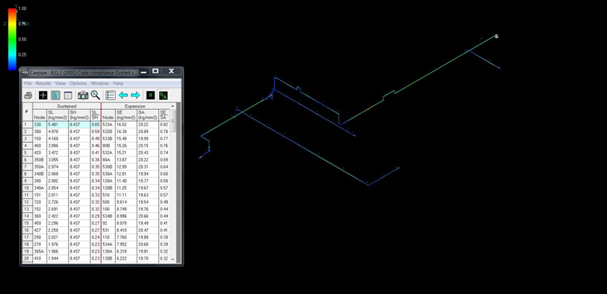

Water Reservoir Pump House Piping Design (ASME B31.3)

Surge & water hammer analysis of conceptual piping design conducted for 4 different operational scenarios (pump power failure, instant valve closure etc. 4 different stress analysis conducted. Maximum forces sorted out. Pipe shoe & saddles analysed and design check verification conducted.

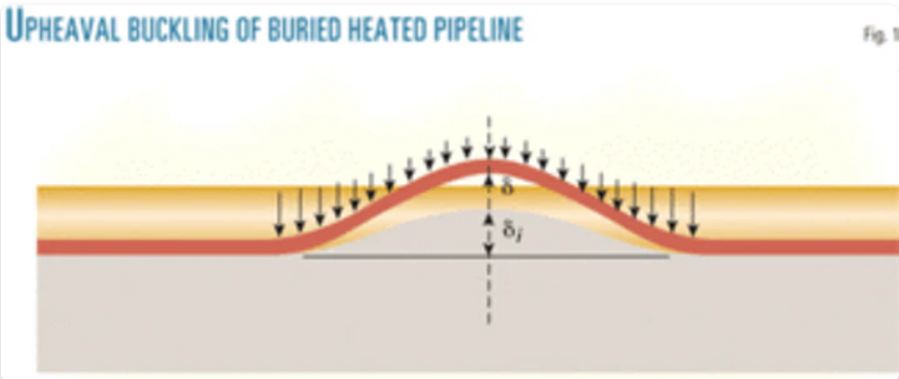

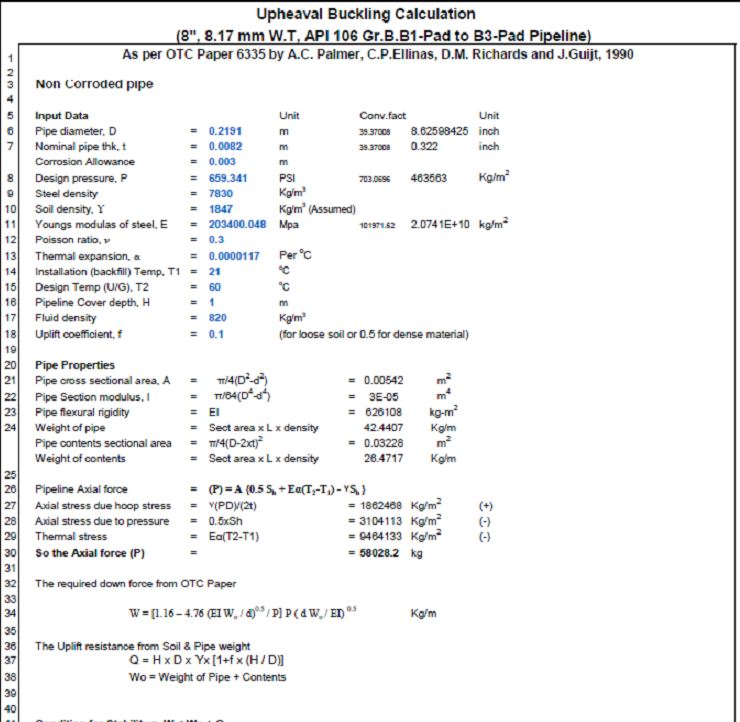

Upheaval Buckling Analysis of Underground Crude Oil Pipeline.

Crude Oil transfer pipeline with 12 kilometers of DN 200 ( ASME B31.4) has been analysed for upheaval buckling check as per OTC paper 6335.

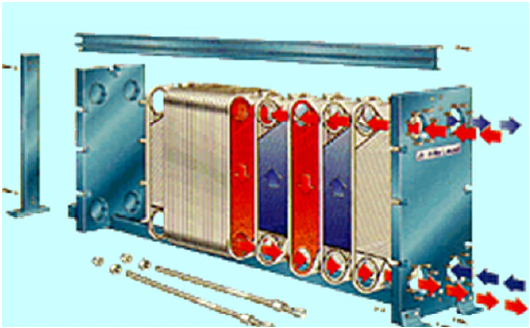

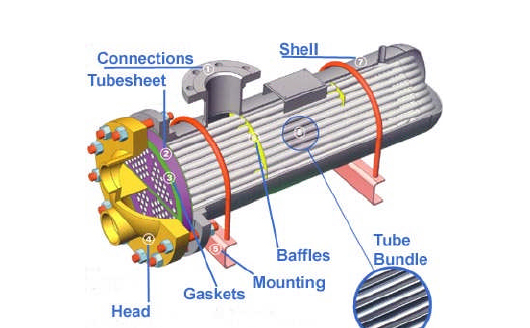

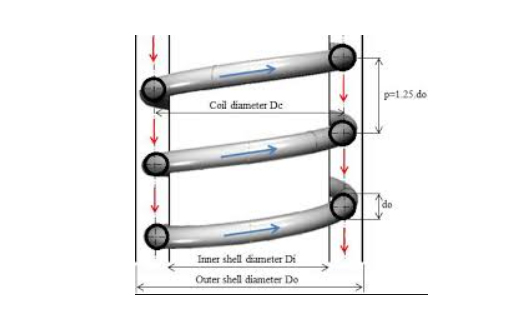

Sizing of 85 Tons/hour hot water exchanger for HEPP.

85 tons/hour 30 C hot water cooling down to 23 C where the raw water temperature is 20 C. A Plate, Shell & Tube, Submerged Pipe Coil Type heat exchangers are modelled. Submerged Pipe Coil Type heat exchanger modelled in Ansys for CFD and heat transfer.

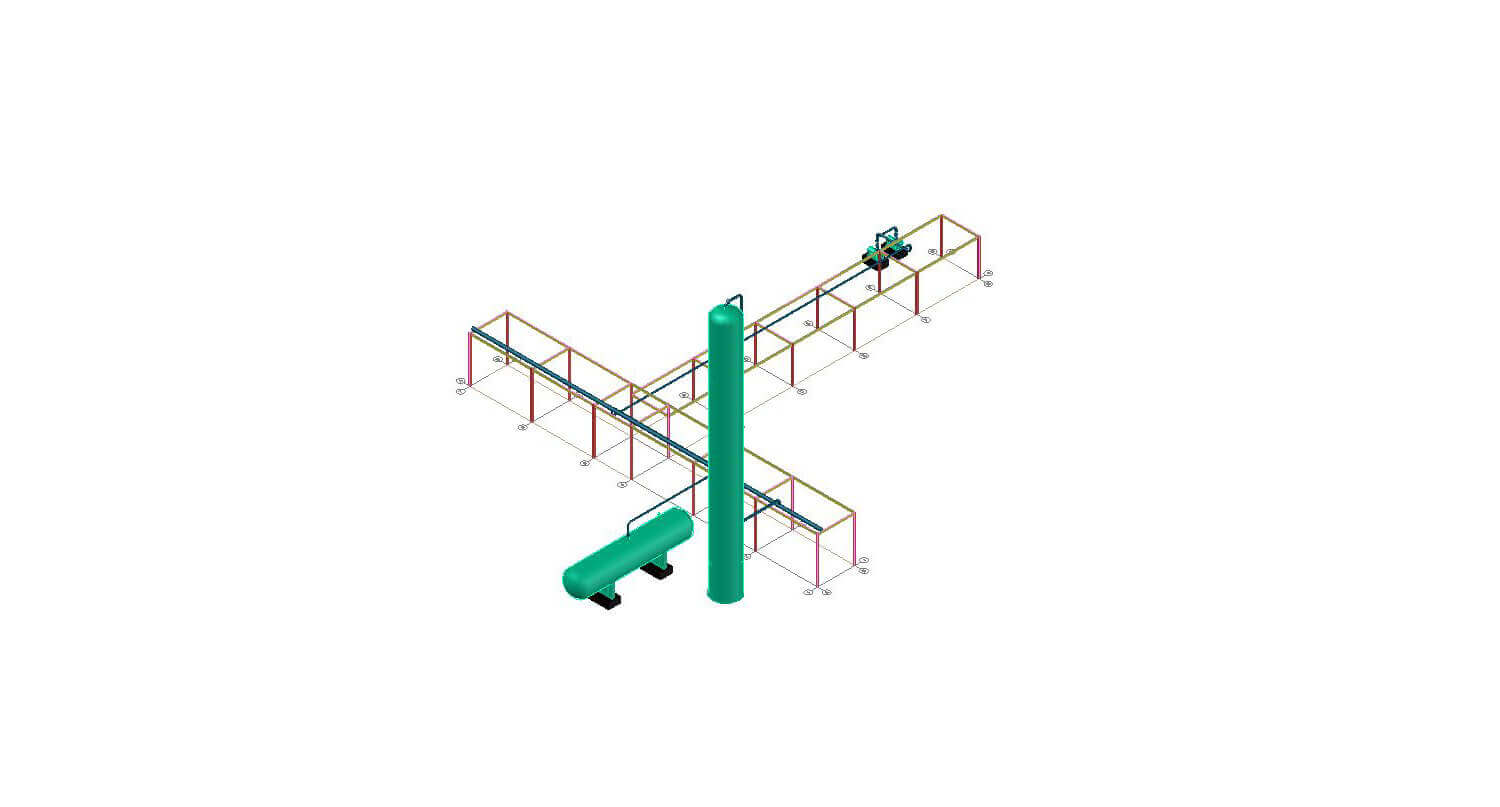

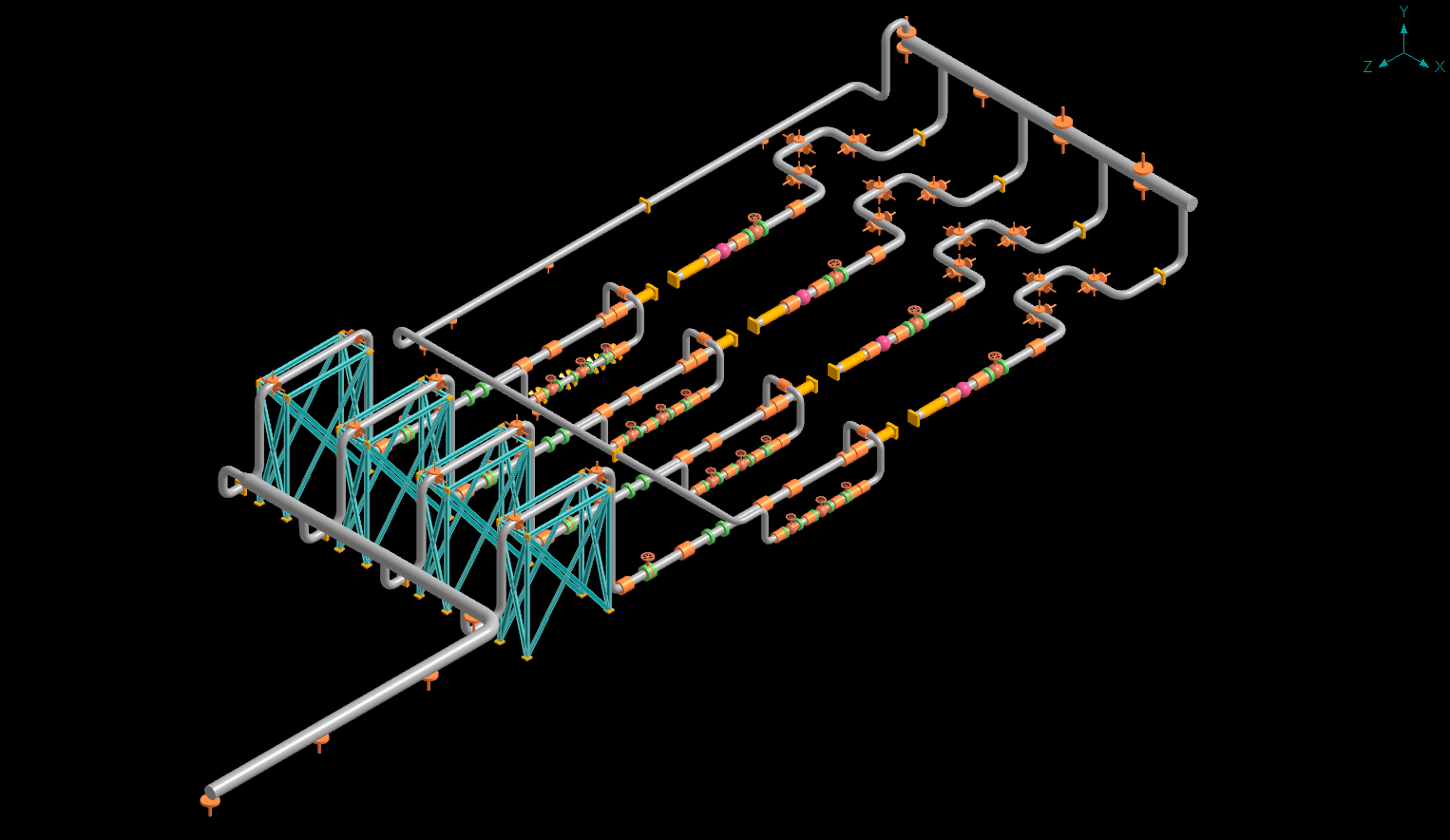

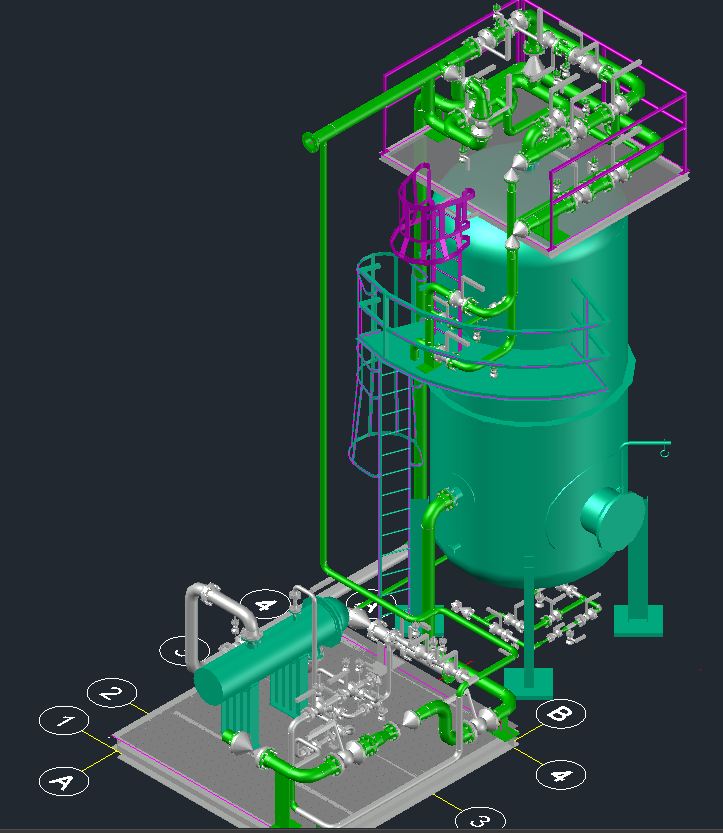

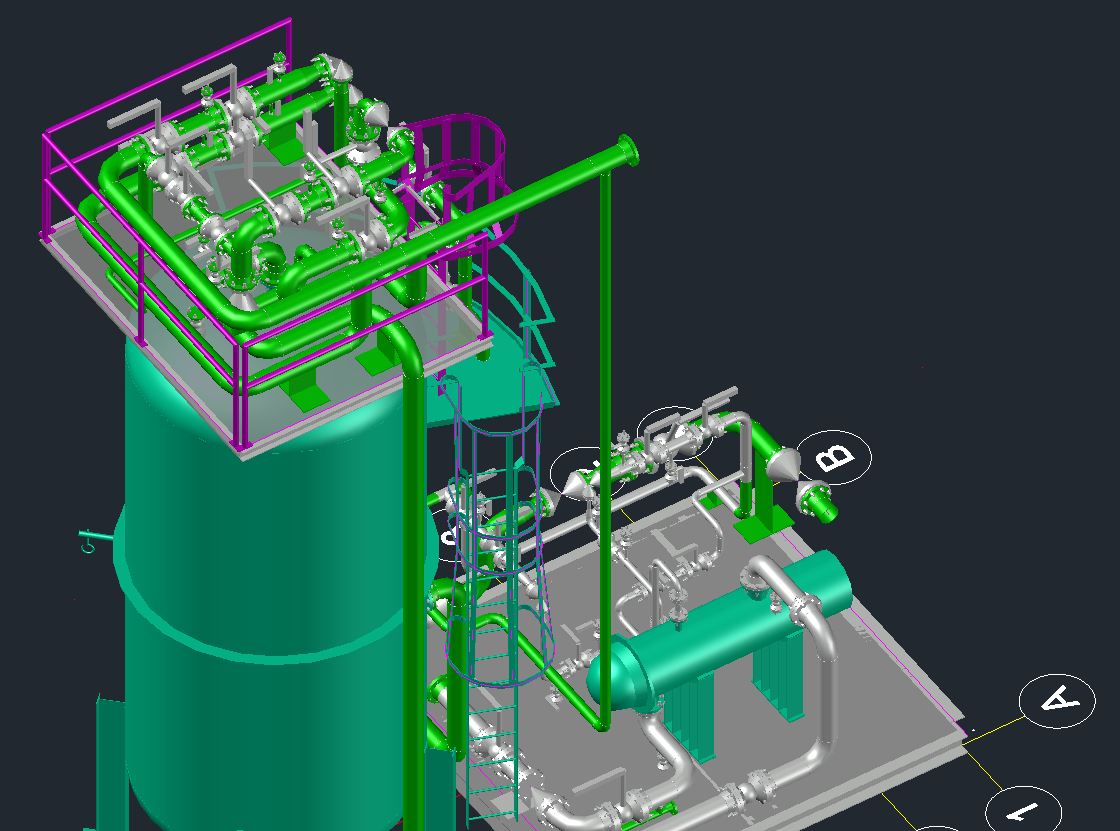

Fuel Gas Heating Skid Design(ASME B31.1)

3D Model of fuel gas heating skid unit has been developed based on Client’s P&ID.

Project Deliverables are :

Pipe stress analysis, C.O.G. calculation, Lifting calculations, isometric drawings, steel prefabrication drawings, BOMs.

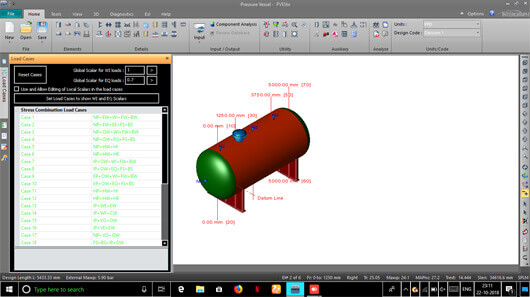

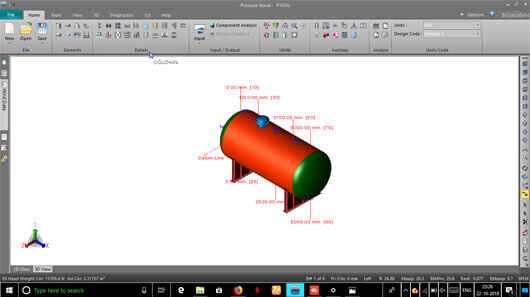

Ammonia Pressure Vessel Stress Analysis

100 cum capacity of horizontal ammonia vessel stress analysis with PVElite ASME Sec. VIII.

Steam Turbine Piping

Steam Turbine piping design as per stress analysis (ASME B 31.1) considering nozzle allowable loads given by turbine manufacturer.

HYOSUNG SPANDEX PLANT PROJECT

OWNER : HYOSUNG SPANDEX

LOCATION

Çerkezköy /TEKİRDAĞ / TURKEY

CONTRACT

680 Tons of Steel Structure Pre fabrication & Erection Works

12 No’s of DMAC Storage Tanks Pre fabrication & Erection Works 24.000 mts 145.000 dia inch Piping & Welding Works 92 Pcs& 450 Tons of Equipment Erection Works Pipe & Equipment Insulation Works

ENTEK STG RELOCATION PROJECT

| OWNER : ENTEK ELEKTRIK / KOCHOLDING |  |

|

LOCATION

Bursa / TURKEY

CONTRACT

12 MW STG &CondenserSystemsReverseEngineering, Dismantling, Transport, Relocation , Design, Installation , Start – Up, PerformanceTests

STG Steam & Condensate Piping Design & Construction Works

TEJCEN AMONIUM PLANT STORAGE TANKS PROJECT

OWNER

GAP INSAAT A.S. / TURKEY

LOCATION

Tejcen / TURKMENISTAN

CONTRACT

Total 395 tons of 3 No’s Carbon steel storage tanks pre fabrication,

1 Impact test edcarbon steel amonium storage tank

2 Carbon steel storage tanks

YASHLIK PULP & PAPER MILL PROJECT

OWNER

GAP INSAAT A.S. / TURKEY

LOCATION

Yashlik / TURKMENISTAN

CONTRACT

Total 300 tonsofA/G & U/G pipingworks

150 Tons of stainless steel piping works

ADAPAZARI – GEBZE CCPP PROJECT

OWNER

ENKA TEKNIK / TURKEY

LOCATION

Adapazarı / TURKEY

CONTRACT

Natural GasPipelineand 480.000 Nm3 / h RMS-A Installation Works

20 Inches Underground Pipeline (75 Barsand 4000 Meters) RMS-A Gas Station Installation Works Turnkey

İZMİR CCPP PROJECT

OWNER

ENKA TEKNIK / TURKEY

LOCATION

İzmir / TURKEY

CONTRACT

Natural GasPipelineand 320.000 Nm3 /h RMS-A Installation Works

16 Inches Underground Pipeline (75 Barsand 1000 Meters) RMS-A Gas Station Installation Works Turnkey

TURKMENBASHI REFINERY LUBE-OIL PROJECT

OWNER

GAMA A.Ş. / TURKEY

LOCATION

Turkmenbashi / TURKMENISTAN

CONTRACT

AboveGroundPiping Works

1700 Tons of Carbon Steel Stainless Steel Alloy Steel Piping Pre fabrication & Erection Works